0

-

An empty cart

You have no item in your shopping cart

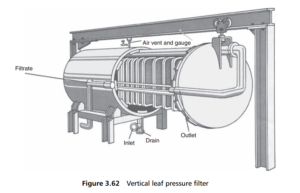

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121The leaf filter incorporates an array of flat filter elements, with filter media on both sides of the element, each one parallel to its neighbours and hanging, equally spaced, from a horizontal support that is also the filtrate offtake pipe. The array is

enclosed in a pressure vessel, usually circular in cross-section, and there is often one hinged or removable end to this vessel, which may be opened and the array of leaves pulled out for cleaning, as in Figure 3.62. Liquid flows into the shell of the

enclosing vessel, through the medium on the leaf to the top of the interior of the leaf, and out into the filtrate collection manifold.

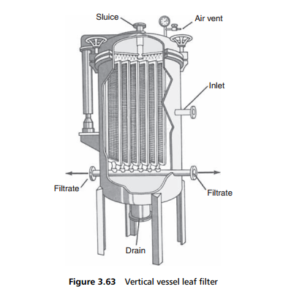

An alternative arrangement of vertical leaf pressure filter has the leaves supported on the filtrate manifold from below, with the whole enclosed in a vertical cylindrical shell, as shown in Figure 3.63 . The leaves are now of different widths, according to the chord of the cross-sectional circle that they occupy. This version of the vertical leaf pressure filter is the least expensive of the pressure leaf and plate filters.

All versions are normally available with wet (i.e. re-slurried) or dry cake. Wet discharge is achieved by the washing of the cake off the leaves, using sprays or a sluice. The sluice may oscillate to ensure that the cake is washed from the whole

of the leaf surface. The washing action resuspends the solids in a slurry (usually thicker than the original feed suspension), which is then drained or pumped out of the containing vessel.

Dry discharge can only occur after all of the feed suspension has passed through the filter (with the help of a scavenger plate close to the bottom of the shell if necessary). An air blow may be used to dewater the cake, and a reverse blow to discharge

the cake. The leaves may alternatively be freed of cake by use of scraper blades, or be subject to vibration to shake the solids free. However it is done, the cake falls to a conveyor below the filter (usually through doors in the shell) or below the leaf

array if it has been removed from the shell as in the filter in Figure 3.62 .

Vacuum leaf filters are less common, although cheaper than the pressurized version, because of the lack of a pressure vessel. They consist of an open tank full of the liquid to be filtered, into which the array of vertical leaves is submerged. Vacuum is applied through the filtrate manifold, and cake builds up on the leaves until cake removal becomes due. This kind of filter is mostly used with precoat as a clarifying filter, which is not only cheaper but also more easily inspected and maintained.