0

-

An empty cart

You have no item in your shopping cart

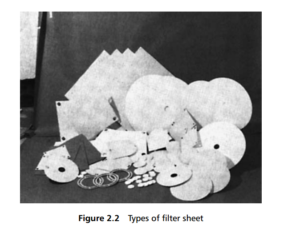

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121Filter sheets are made in the same way as paper, i.e. by wet laying, but they are both thicker than paper and rougher in texture. They have traditionally been used in forms of filter presses and employed to clarify beverages such as beer and whisky or to sterilize pharmaceutical solutions. An array of filter sheets is shown in Figure 2.2. These sheets closely resemble thick filter paper and, in fact, were originally made from a mixture of cellulose and asbestos fibres; recent years have seen asbestos displaced, because of its health hazards, by kieselguhr. Because of the importance of the polishing duties performed by the sheet filter, the cellulose-based sheet is now being replaced by membrane filters.

For further information, please click here.