0

-

An empty cart

You have no item in your shopping cart

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121The alternative approach to match flow direction with pore size is to undertake the filtration in upwards flow. With an upflow sand filter, flow is from the bottom through to the top of the bed. The result is that the entire bed depth is utilized to

trap solids, with the fine top layer acting as the final cleanup zone. This gives a suspended solids capacity of 29 to 48kg/m2, depending on the density of the suspended matter, a greater capacity per unit of surface area than in a conventional

downflow filter. A bed stabilizer is necessary at the top of the bed, to keep it in place during the high on-stream flow rates, in order to take full advantage of the bed ‘s capacity to retain trapped solids. The bed is cleaned by upwards flow of backwash liquid, but the bed is expanded by air agitation prior to washing, in order to achieve maximum cleaning efficiency. This mode of operation allows the upflow filter to handle turbid waters at high flow rates with longer cycle lengths, while ensuring good cleaning cycles.

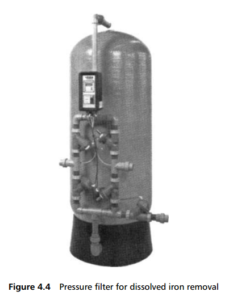

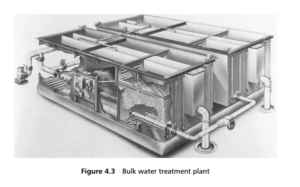

The bulk filtration units so far described operate under gravity, because they involve very large quantities of raw water and, in consequence, are very large units in order to cope with the flow ( Figure 4.3 ). A possible alternative approach is to pressurize the containing vessel, and pump the raw water into the filter, so increasing the pressure differential across it and thereby increase the flow rate. This is a much more expensive process, and tends to be used for small demand/high quality

treatments, which may involve chemical processes as much as filtration.

Thus, Figure 4.4 shows a pressure vessel filter, operating in upflow mode, and developed for the removal of dissolved iron from water supplies. The filter medium takes the form of a bed of catalysed manganese dioxide in granular form, approximately 1m deep. This medium has the ability to cause dissolved iron to react with the oxygen present in the water to form insoluble iron oxides, which will precipitate and be retained by the bed. Cleaning is then undertaken by a high velocity backwash process which fluidizes the bed medium and removes the precipitated iron.