0

-

An empty cart

You have no item in your shopping cart

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121The major development of the deep-bed filter has been to allow the bed material to move continuously down through the filter vessel, and then to be carried back up to the top of the bed, through a cleansing zone. Manufacturers have concentrated

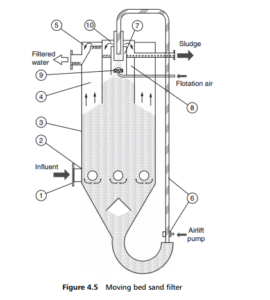

on the development of the moving bed filter, which provides better cleansing of the bed, and which does not have to be shut down for back washing. It is thus a truly continuously operating filter. Figure 4.5 shows an example of a typical continuous self-cleaning sand filter. It has no mechanical moving parts yet it is possible to obtain feed flow rates of up to 25m3/h per square metre of filtering area.

The main structure of the filter is a cylindrical tank with a conical bottom. In operation, the raw water is fed in (1) where an inlet system, and (2) evenly distributes the flow into the filter bed. This bed is made up of sand of a predetermined

grain size, selected according to the nature and quantity of suspended solids in the raw water. The water flows through the sand bed and leaves the filter at the overflow weir (5). The sand bed moves continuously downwards, being sucked from

the bottom by an airlift pump (6), which carries the dirty sand upward to the top of the filter into the sand washer (7).

The washed sand falls back into the filter through the chamber (8). The pressure drop across the filter remains at a constant low value by virtue of the continuous washing process that keeps the filter bed clean. The heart of the system is the sand

washer, which, via the airlift, receives a concentrated mixture of sand, water and dirt particles; the dirt is separated from the sand by flotation due to the action of micro air bubbles generated at the air diffuser (9). The sand washer is designed to

clean each grain of sand by scouring. The dirt particles are floated upward by the air bubble action and leave the filter over the sludge weir (10), and are carried away by some of the wash water. This reject water is a small fraction of the total water

fed to the filter, and is returned to the filter inlet after the sludge is dewatered.

It is recommended that a filter screen be used ahead of and in conjunction with filters of this type. Continuous self-cleaning filters of this kind are considered to be one of the most reliable types of bulk water filter available, with low plant costs

and high clarification efficiencies. A full scale array of moving bed filters is shown in Figure 4.6 .

Look for more information, please click here.