0

-

An empty cart

You have no item in your shopping cart

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121Our ready-to-use covers for rotary disc and hyperbaric rotary disc filter segments are adapted to the needs of this filter type. Waterfiltech’s fabric solutions are outstanding in terms of cake release and abrasion resistance.

Customization accepted.

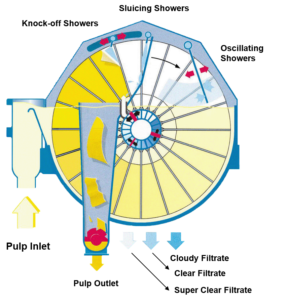

Rotary Disc Filter is used extensively in pulp processing and chemical and mineral processes, but also in any filtration process which requires a large volume of filter area to de-water and dry the product.

Covers for rotary disc filters are available in PP, PVDF or PA fabrics, with pore sizes down to 20 µm. We offer different designs for 15° or 30° segments equipped with special zipper closures, and center seals, including rubber sealing gaskets.

Cake forming takes place on the discs when they rotate through the slurry.

Solids discharge: As the disc filter rotates, the cake is dried by removing the liquid and is discharged from the cloth at the end of this zone by means of compressed air. The cake then drops into the discharge chute.

Request for catalog or technical support, please click here. ![]()

You must be logged in to post a review.

Reviews

There are no reviews yet.