0

-

An empty cart

You have no item in your shopping cart

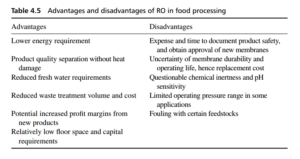

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121Reverse osmosis is used to considerable advantage in the food and dairy industry, the main reason being the cost reduction compared with evaporation consequent upon the elimination of this process. Some advantages and disadvantages of reverse

osmosis in food processing are given in Table 4.5 .

Applications of reverse osmosis in the dairy industry include water treatment, fractionation, product and chemical recovery, concentration and denaturing. The concentration of process streams from around 10% total solids to 25% can be achieved at a lower cost than by evaporation. Also there is a considerable reduction in volatile flavour component losses and in adverse changes to heat sensitive components (protein denaturation). Reverse osmosis also reduces discharge volumes to water treatment facilities and produces reusable water.

The performance of reverse osmosis in concentrating milk is limited by the osmotic pressure and most commercial modules have operating pressure limits of 30 to 40 bars, which limits the concentration of milk to a factor of three to four. In

the production of skimmed or whole milk powder, the milk is usually concentrated to 45 to 50% total solids before spray drying. Thus reverse osmosis cannot substitute entirely for conventional evaporation, rather it is used as a pre-concentration

step before evaporation, to reduce operating costs or to increase capacity of existing plant. The relative energy consumption of reverse osmosis and thermal concentration methods in the concentration of milk differ by an order of magnitude, and with

thin film composite membranes the cost of reverse osmosis is lower still.

The ultrafiltration of milk using polysulphone or polyethersulphone type membranes has a number of applications. The ultrafiltration of milk on farms as a means of reducing refrigeration and transport costs, and the production of speciality milkbased beverages are attractive uses. Cheese manufacture using ultrafiltration is another area where the use of membrane filtration is becoming more widespread in the dairy industry.

The fractionation of whey by ultrafiltration to produce protein concentrates can increase the initial protein content from 10 or 12% (dry basis) to 35, 50 or even 80% protein with little loss in whey protein functionality. Demineralization of whey can be achieved by ion exchange, electrodialysis and nanofiltration.