0

-

An empty cart

You have no item in your shopping cart

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121Industrial wastes differ from municipal wastes in three main respects: they are usually much stronger in waste material content (both inorganic and biodegradable); they are often acidic or alkaline in nature rather than neutral; and they frequently contain highly toxic materials. The presence of oils, either as droplets or as an emulsion, is also a problem with much industrial waste. On the other hand, the wastes coming from a particular factory are usually fairly constant both in quantity and composition.

The annual cost of treating industrial wastewater and its resulting sludges is huge, but is still far below the level needed for good health around the world. There is comprehensive legislation in place in most industrialized countries governing the

discharge of wastewater from industrial sources, yet pollution from such wastewater coupled with poor wastewater treatment remains a major concern for the whole world. Despite the relatively strict enforcement of the appropriate regulations in many countries, many industries are still failing to regard wastewater seriously, often through ignorance of the regulations and a lack of basic understanding as to what kinds of wastewater treatment technology are available. Wastewater treatment is thus a complex task for environmental management.

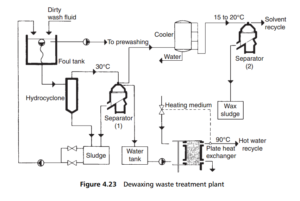

Most industrial wastewater treatment plants are in two major sections: the first to deal with the particular product of the factory, and the second to deal with the general wastes, and perhaps the effluent from the first stage, which uses the same general scheme as that for municipal sewage. The main function of the first stage is, or should be, the minimization of the loss of any product material in the waste, i.e. it should be regarded as a material recovery process rather than as waste treatment. This may be quite a complicated process, as shown in Figure 4.23, which illustrates a waste treatment plant for a vehicle dewaxing process, designed to recover the dewaxing solvent and produce a water that can easily be treated by a conventional two-stage process.

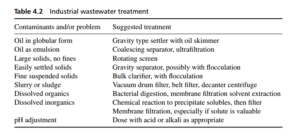

A general guide to the methods used for the specific industrial waste treatment stage is given in Table 4.2 . Obviously, if more than one type of contamination is present, then treatment appropriate to each will be required.

The presence of oil in wastewaters is common – and methods of dealing with it are illustrated later in this Section (and also in Section 5). The other main problem with industrial wastewater is dissolved material, whose concentration is above

the levels permitted in discharges across the factory boundary. For organic materials, which are not wanted, digestion with specific bacteria may be the best solution, although a final pass through the equivalent of an activated sludge system may

still be required. Membrane filtration, especially ultrafiltration, will separate most organic materials without destroying them (although producing a concentrated organic waste if the materials are not wanted), while solvent extraction can be used to recover specific organic materials.

The recovery of dissolved inorganic materials can be achieved by evaporation and crystallization, although membrane filtration is probably a more economic process. If the materials are unwanted, then membrane separation will still remove

them from the liquid wastes, but only as a concentrated solution, still in need of treatment. Chemical reaction, probably also involving pH adjustment, to convert the dissolved salts into an insoluble precipitate, is an attractive treatment process,

with filtration of the precipitate from the resultant suspension.

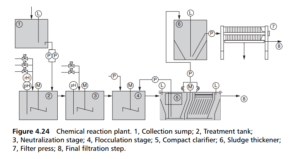

Figure 4.24 is a schematic flow sheet for a continuous reaction and dosing plant for the removal of waste inorganics. The raw waste is accumulated in a collection sump (1) and then pumped through a series of reaction tanks (2–4) whose functions

may be neutralization, precipitation, and flocculation of the precipitated solids. The resultant slurry is settled in a clarifier (5) from which the clarified liquid flows on (8) to discharge if clean enough, or to a polishing filter or a general sewage treatment works. The sludge from the clarifier is thickened (6) and then dewatered in a filter (7) or decanter centrifuge, with the filtrate joining the clarified liquid flow (8) (or being returned to the clarifier).