0

-

An empty cart

You have no item in your shopping cart

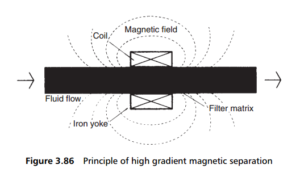

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121The attractive force exerted by a magnet on other magnetic materials in its vicinity is at any point proportional to the magnetic field and the magnetic field gradient at that point. A simple way of introducing large field gradients is to use a magnet in a highly sub-divided form, such as an assembly of fine wires or balls of a few mm in diameter. Large field gradients are then set up at the surface of the balls or wires.

The most efficient form of magnetic filter is one in which a large magnetic field is produced in a region occupied by a magnetic matrix in sub-divided form. This arrangement is used in high gradient magnetic separation (HGMS) systems, as

indicated in Figure 3.86 .

Within this general arrangement there is considerable scope for design variations to meet the requirements of particular applications. For example, the magnetic field may be produced with zero power consumption, using a magnetized iron yoke. However, for ease of cleaning the filter, and also for reasons of economy of space, it is generally preferable to use a small yoke in association with electromagnetic coils. The shape of the yoke can be varied in a number of ways to obtain results compatible with the customer ’ s requirements. Different filter matrices, such as expanded metal and ball bearings, are used depending on the application.

Ask for more information, please click here.