0

-

An empty cart

You have no item in your shopping cart

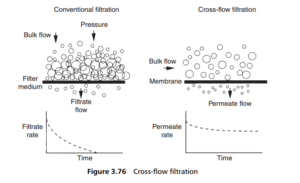

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121The cross-flow principle ( Figure 3.76) began with the hollow fibres used in reverse osmosis, and has expanded to become one of the most important components of the filtration industry. In order to keep the surface free of deposit, high-shear conditions are employed, and these can be created either by a high suspension velocity across the medium, or by some sort of movement (rotation, vibration, etc.) of the medium with respect to the liquid flow or a nearby non-porous surface. This latter group, of movement promoted filtration, is often termed dynamic cross-flow filter systems.

Cross-flow filtration can be classed as one of a number of thin layer filter systems. It is one of the three main practical filtration processes (the others being cake filtration and depth filtration, with surface straining being a less-used fourth process).

The dynamic cross-flow filters address the problem of the reduction of flow through the filter medium (filtrate flux), which is caused either by fouling of the membrane surface and consequent blockage of the pores in the membrane, or by the increase in concentration of the particles or large molecules as they approach the membrane, but are not being allowed through it. The fouling and increased concentration will both restrict passage of the liquid to and through the membrane. The dynamic systems reduce the impact of fouling or concentration polarization by agitating the zone close to the membrane surface in some way so as to create additional shear in it.

The VSEP (Vibratory Shear Enhanced Processing) system made by New Logic Research is an example of the vibration technique. It uses a stack of circular membrane discs, each with membrane media on both sides, enclosed in a relatively

small housing (over 100 m2 of membrane area in less than 200 litres of housing volume). The stack is then vibrated torsionally, i.e. in a direction parallel to the discs.

A similar stack of discs may be rotated about the central axis to give rotational promotion of shear, but this arrangement is improved if a stationary non-porous disc is mounted between each pair of membrane discs. The opposite arrangement

with stationary membrane discs and rotating non-porous discs is equally effective.