0

-

An empty cart

You have no item in your shopping cart

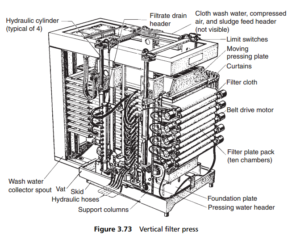

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121The great success of the filter press has led to several other designs of filter employing the plate principle, most notably the vertical filter press (or tower press as this type is sometimes called – but so is a type of belt press, discussed in Section 3P), which is basic ally a filter press stood on one end with a continuous band of filter medium passing progressively over each plate in turn. This arrangement can add gravity to the hydraulic head as a driving force, and also means that the cakes form evenly without the slippage cracks occurring in the horizontal filter. Washing can thus be uniform as well.

The vertical filter press, like the horizontal press, is strictly speaking a batch operating filter, but is more correctly called a semi-continuous filter, because the cake is discharged from all of the compartments at the same time. When the filtration cycle starts, the plate assembly (Figure 3.73 ) closes, and slurry is fed to all of the compartments at the same time. Cakes form on top of the filter medium in each compartment. Once filtration is complete, diaphragms are forced hydraulically down on the cakes to dewater them. Then the diaphragms are relaxed, wash water is introduced, and the cakes squeezed once again, followed by a compressed air blast to dry them further. At this point, the plate assembly opens, and the continuous band of filter medium advances

one compartment’s length throughout the whole filter. As it does so, it passes over small diameter rollers at each end of the compartment, breaking away the cakes, which fall into collection troughs below the filter. The filter medium is now reversed (the bottom side is now facing upwards and vice versa), so it is washed, and the process repeated.

The vertical filter press is a very effective unit, fully automatic in operation, though somewhat expensive. It occupies less floor space than a horizontal filter press of the same filtration area.