0

-

An empty cart

You have no item in your shopping cart

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121The requirements for dust filtration vary considerably with the particle size of the dust material, and with its concentration in the suspending air or gas (and also with the velocity of the suspending gas). Where the concentration of the solids is reasonably high, the most likely separator would be a cyclone, or even a simple settling chamber, which would also be used (at least as a first stage separator) when particles are present with diameters approaching 0.5mm (500um). As was stated in Section 1B, some 90% by weight of all airborne particulate impurities range from 0.1 to 10 um in size, although this range and the actual concentration of solids will vary markedly.

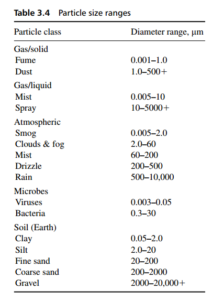

Some indication of the size ranges of various classes of particulate material is given in Table 3.4 , from which it can be seen that dust collection is primarily concerned with particle sizes of 1um and above.

As far as fine dust separation is concerned, it is the range of filters that is largely concerned, both the two types covered here, and those of Sections 3K and 3L.

Dust collection mechanisms include all of the entrapment processes described in Section 1C, with the effect of electrostatic forces also being very important in many systems. Filtration of dusts is achieved by depth filtration – for which the filter pad is very effective – and by the combination of surface and cake filtration that the pleated sheet media do so well. The two materials have vied with one another over the years as to which can achieve the highest degree of separation, a history of success that is largely determined by the development of new materials of one kind or the other.