0

-

An empty cart

You have no item in your shopping cart

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121The fixed bed centrifugal filter is thus a batch-operated device for recovering solids from liquid suspension. All types have cylindrical baskets, open to the atmosphere (or to the enclosing casing) at one end. Filtrate passes through the filter medium

and the developing cake, into the casing and so to a filtrate receiver. The formed cake must then be removed at the end of the batch, this removal being the main design feature of the centrifugal filter.

The basket is mounted on a drive shaft, which may be directly coupled to the drive motor, or the motor may sit to one side of the centrifuge, with a pulley and belt connection to the drive shaft. The axis of the basket may be vertical, with the open end at the top (the reverse orientation, with open end at the bottom is perfectly feasible, but rarely seen), and with suspension feed through the open end. Cake removal can be through this open end, or through openings in the base, provided that the drive mechanism is properly enclosed.

The basket orientation can also be horizontal, which is the preferred case for the more complicated semi-automatic and automatic discharge versions. An inclined orientation is also possible, although less common.

One of the problems of centrifuge operation is the uneven laying down of the cake, which can cause out-of-balance forces in the rotation, with consequent vibration. The most common way of dealing with this problem is by supporting the basket at three points around its circumference. Such an arrangement with a three-column suspension is shown in Figure 3.29 (which also shows a number of internal items, for cake washing and discharge). An alternative to this support from beneath is the use of a top driven shaft from which the basket hangs – the pendulum centrifuge.

A three-column basket centrifuge can be equipped to handle various filling, washing and discharge requirements in a discontinuous filtration process, with minimum attrition of the solids. The suspension to be separated enters the machine

through a stationary feed pipe or over a rotating feed cone at the bottom of the basket. The feed cone is designed to effect a very gentle acceleration of the suspension up to basket speed. When the basket is full of solids, the feed valve is closed off, frequently by automatic control. The subsequent process consists of drainage of the mother liquor, washing of the solids, drainage of the wash liquid and finally discharge of the cake.

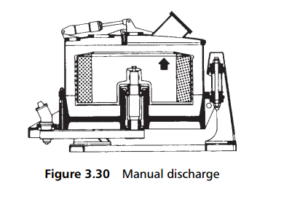

The simplest way in which discharge can be effected is to stop the rotation of the basket and then to dig out the accumulated cake by hand, through the open top of the basket, a situation illustrated in Figure 3.30. Slightly more complex is to use a

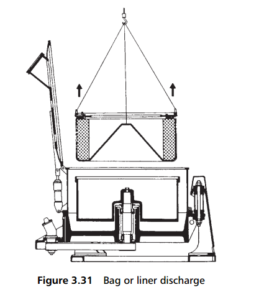

cloth bag or an inner basket, and to lift this out, with all of the cake, as shown in Figure 3.31. Bag removal ensures that no solids are left behind. For both of these methods, the centrifuge must first be brought to rest.

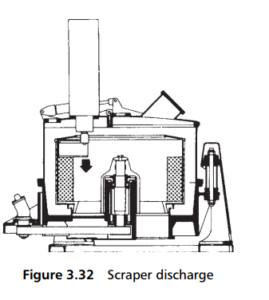

A further increase in complexity involves the use of a paring knife mounted on the top of the centrifuge casing, which slices the cake off the inside of the basket, as shown in Figure 3.32. The cake solids then fall through openings in the base of the

basket, to be collected below the centrifuge. If the nature of the accumulated cake is

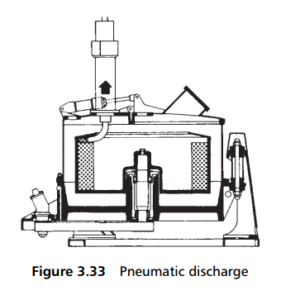

suitable, then the knife may be replaced by the tip of a vacuum pipe, which sucks the cake away from the basket, to be carried up and away by a pneumatic transport system, as in Figure 3.33. In either of these cases, the centrifuge is still rotating as the

solids are removed, possible at full speed, but the paring knife or suction pipe cannot be allowed to touch the filter medium, for fear of wearing it away. As a result, a heel of unremoved cake solids is left on the filter medium. This is not a problem if the next batch has the same composition as the first, but if the solids differ, then the heel has to be washed or dissolved away before the next batch can be filtered.

A major application for the perforate basket centrifuge of this type is in the separation of sugar crystals from the mother liquor after crystallization. Indeed, they are then called sugar centrifugals.

As can be seen from the drawings of Figures 3.30 to 3.33, the vertical basket centrifuge can be fitted with a lid. Whilst this may be to give containment against splashes, it can also be made gas-tight, so the centrifuges can be used for hot or toxic suspensions, or to contain organic vapours.

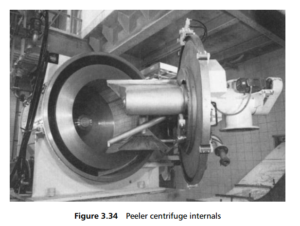

The major group of centrifugal filters with horizontal axes of rotation all have a scraper blade or knife, which cuts into the dewatered cake in a peeling action, so that the slices of cake fall into a duct that carries the solids out of the open end of the basket. The peeling knife may extend the full width of the cake, or it can reciprocate across the cake at the same time as cutting into it. A typical peeler centrifuge can be seen in Figure 3.34, showing a full-width peeler knife, and a solids

discharge duct fitted with a screw conveyor.

The peeler centrifuge of Figure 3.34 can also be sealed against vapour loss, or given a nitrogen blanket to protect the cake (or filtrate) from air oxidation.

As with the basket centrifuge, the peeler centrifuge operates in the full filtration cycle of filling, draining, washing dehydrating and finally peeling. This adjustable batch cycle is in most cases controlled automatically. The various operations within a batch can be performed at constant or varying speed of the centrifuge basket, it being quite normal to reduce the rotational speed during the peeling process.

In operation, the suspension is fed into the rotating basket through a feed valve. The feed step is interrupted by a feed controller as necessary, and feeding is repeated until the basket is filled. Filtration begins during the feed process and is

completed when the level of the mother liquor submerges under the cake surface. A wash valve, controlled by a timer or flow meter, directs the wash liquid onto the cake through a wash pipe provided with spray nozzles. A conically shaped housing

allows for the separation of the mother liquor from the wash filtrate, which is a particular advantage for multi-stage washing.

The dry spinning stage is completed after the wash liquor has passed through the cake and the dry solids are removed by the hydraulically activated peeling device, down to the residual cake heel. The peeled solids are removed from the basket through

a chute or by a screw conveyor. The residual heel left in the basket after a batch of solids has been removed serves as the primary filter medium for the next cycle, and so on, until it becomes impermeable and needs to be removed by washing with filtrate.

Application examples for the peeler include bulk chemicals, fine chemicals and pharmaceutical products, petrochemicals, foodstuffs and related products. For pharmaceutical and fine chemical applications some peeler centrifuges incorporate fully

automatic steam sterilization for clean-in-place requirements.

Centrifuges with rotary siphons are similar in many ways to conventional basket filtration centrifuges except that the filtrate, having passed through the cake and filter medium, is not discharged into the centrifuge housing, but flows through channels and holes in the basket bottom, directly into a ring-shaped siphon chamber, where it is removed with a siphon skimming pipe. An additional filtration pressure is then produced by the difference in level between the filter medium and the siphon position, thus increasing the filtration rate. The siphon chamber/basket area permits backwash liquid through the ring chamber into the inside of the basket. Liquid is forced to permeate the residual heel, and thus resuspends and regenerates it. At the same time, the backflush liquid creates a pool into which the next batch cycle is fed, thus ensuring

that the solids are uniformly distributed. The manner of feed for this design reduces the likelihood of feed imbalance that can come with conventional centrifuges.

The imbalance can come with peeler centrifuges as the feed solids settle unevenly in the basket. The imbalance cures itself (flow is greater through the thinner cake areas), but can cause serious vibrations of the centrifuge for short periods. For this

reason, vibration absorbers such as spring elements, vibration dampers or an inertia block should be fitted when the centrifuge is installed.