0

-

An empty cart

You have no item in your shopping cart

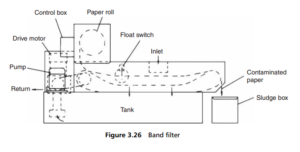

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121Unlike the other horizontal belt filters, the (paper) band filter is a device used for clarifying machine tool and similar coolants and lubricants free of contaminants. It began as a means for holding a sheet of paper through which the oil/water emulsions could flow, and has developed into quite a sophisticated continuous filter.

An automatic band filter consists of an endless honeycomb wire mesh belt that carries the filter fabric through a trough containing the liquid to be filtered. Originally using paper, such filters now increasingly use nonwoven filter fabrics.

The liquid to be cleaned enters through an inlet onto the filter medium, which is held in a pool of the liquid by the endless belt ( Figure 3.26 ). The contaminated liquid is cleaned by passage through the filter medium. As filtered solids build up, the permeability of the fabric decreases, causing the liquid level in the pool to rise

until a float switch is triggered. This causes the filter belt to move forward automatically, carrying the dirty filter fabric out of the pool so that it can be dumped into a sludge collection box. The same movement unwinds fresh medium from a feed roll

and moves it into the pool, automatically matched to the flow rate of the contaminated fluid and the build-up of solids.

Many filters of this type are capable of providing adequate decontamination of the feed liquid just using the hydrostatic head in the pool, i.e. it is a gravity filter. More complex versions, with more demanding clarifying needs, use media with

higher resistances, and vacuum is then used to drive the filter.

This type of filter has found particular application for the continuous cleaning of coolants and other liquids and emulsions, especially where there is a need to separate particles from liquids similar in viscosity to water, such as machine tool

lubricants, cold rolling mill coolants, and some water treatment or effluent control duties. Flow rates generally run from 20 to 6000 l/min, and if higher flow rates are required, then units can be connected in parallel.

In a large engineering works where there are many machine tools, then a central band filter system will normally be installed to serve all of the work stations. This type of system typically supplies cleaned coolant to transfer lines, special machines and machining centres.

Where clean liquids are constantly required and abraded particles are produced, varying in size, shape and material, an automatic band filter with a nonwoven filter fabric will as a rule provide a cost-effective solution.