0

-

An empty cart

You have no item in your shopping cart

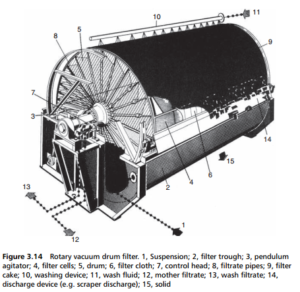

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121A rotary vacuum drum filter consists of a cloth-covered compartmental drum suspended on an axial shaft over a feed trough containing the suspension, with approximately 50 to 80% of the screen area immersed in the suspension. The trough will

usually include an agitator to maintain the feed suspension at a constant concentration.

The oscillating swing-type agitator, which consists of welded side arms and angle rake ploughs, is designed to prevent cake erosion from the drum surface but at the same time to maximize cake formation and production output. Other designs allow

the agitator assembly to be removed from the tank with the drum still in place.

The drum is commonly divided into three sections known as the cake-building, de-watering and cake removal zones. The first two zones are under vacuum, whereby the water in the material being handled is sucked through the filter cloth, and the solid

particles build up as a cake on the cloth. In the third zone the vacuum is released and compressed air jets may be used for cake removal. The compressed air can also be employed for clean-blowing the filter cloth.

A specific design of the rotary vacuum drum filter is shown in Figure 3.14. The drum rotates at 10 to 60 revolutions per hour and a vacuum of approximately 400 to 160 torr is built up with a liquid seal pump that is connected to the drum cells via

the control head and filtrate pipes. This sucks the liquid through the filter cloth, and the solids contained in the suspension are deposited in a uniform layer on the cloth on that part of the drum that is submerged in the feed suspension.

The control head divides the filter drum into the different sections for filtration, washing, suction drying and cake discharge, so that in the course of one revolution each point of the drum area passes through these zones in succession. The filtrate runs off through the separator receiver and is discharged either by pumping or by utilization of atmospheric pressure (i.e. by use of a barometric leg). The filtered solid layer emerges from the suspension as the drum rotates, and following its emergence is washed, suction-dried and discharged from the filter cloth. The wash liquid is fed onto the cake either directly by means of wash devices such as weirs or spray nozzles, or of a wash belt lying on top of the cake.

The filtrate from the wash zone can be drained off separately from the mother filtrate. The filter cake is discharged by means of a discharge device of some kind, which covers the entire drum and which is specially suited to the cake thickness,

consistency and structure (including scraper, roller, string, etc. – described below).

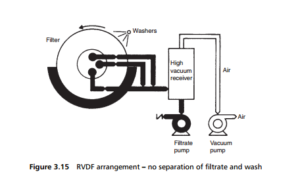

The filter cloth can be cleaned before it returns to the feed trough, either with water jets or with cleaning brushes. As the drum rotates, the cleaned filter is once more immersed in the suspension. If the filter cake is not washed, or if separation of

the main and wash filtrate is not required, then the plant is equipped only with a filtrate separator. An arrangement of filter and ancillaries is shown in Figure 3.15 for the case where the cake is washed, but filtrate and wash liquors are not separated.

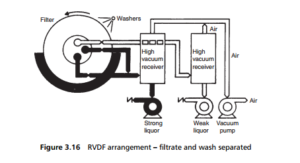

(Instead of the filtrate pump, atmospheric pressure can be utilized for discharging the filter.) A filter system using a common vacuum source, but keeping the filtrate (strong liquor) and wash liquid (weak liquor) separate is shown in Figure 3.16.

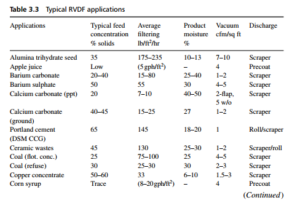

The range of materials handled by rotary vacuum drum filters is shown in Table 3.3. For a long period the RVDF was the main process vacuum filter, a key processing tool in the various industries listed in Table 3.3 , but its role has been taken to a considerable extent in recent years by the horizontal belt filter.