0

-

An empty cart

You have no item in your shopping cart

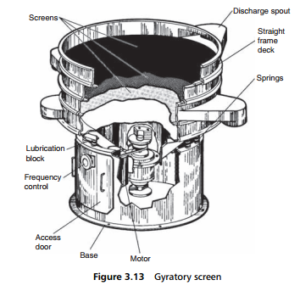

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121Gyratory screen separators, which impart a basically circular motion to the particles on the screen, are used for high capacity separation by size of dry materials, and for wet separations when oversize material constitutes a large percentage of the feed (a typical example is shown in Figure 3.13 ). Common practice with gyratory screens has been to adapt the motion of one type of machine to perform either wet or dry separations, since two distinctly different types of motion are required for the best efficiency.

The separation of solids from liquids requires a crisp, long, horizontal motion to shear the feed stream and quickly pass the liquid through the screen. A minimum amount of vertical motion is used to convey solids out of the separator. Dry separation, on the other hand, normally requires precisely the opposite types of motion – minimum horizontal motion to spread the material over the screen in a controlled pattern, and a strong vertical motion to stratify the product so that particles can quickly pass through the screen openings.

The gyratory screen has become a remarkably useful processing tool, able to separate several solid fractions by the expedient of mounting a series of decks, one above the other on the one vibrating frame.