0

-

An empty cart

You have no item in your shopping cart

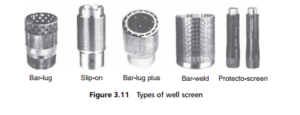

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121Well screens are sleeve-like units fitted over the ends of intake pipes in water or oil wells. They well illustrate the nomenclature problem outlined at the start of this chapter in that they are relatively small and clearly act entirely by straining, yet they have always been called screens, and so are described here. In construction they may vary from simple slotted pipes, with or without a surrounding screen, to quite specialized designs of sleeves, as shown in Figure 3.11 . They consist essentially of a cylindrical tube, sealed at one end, with porous material of some kind in that part of the walls that sit over perforations in the sides of the end of the suction pipe, over which the screen is fastened. They serve to prevent entry of particles of rock from the drill site into the water or oil being extracted.

The lug screen is basically a wire wrap screen located on vertical bars on a perforated pipe, facilitating free entry of fluid over the entire exposed surface of the screen, to increase its efficiency. This principle is further extended in the lug plus

version, where the bars are welded to the wedge-wire screen, and the whole is shrink-fitted to the perforated pipe. The slip-on screen is of similar construction, but is a slip on fit. In the weld screen the wedge-wires are welded to vertical rods.

The ‘ Protecto-Screen ’ incorporates a perforated protective shell guard over the wedge-wire screen.

PVC screens in sizes ranging from around 40 to 220 mm are gaining in popularity, particularly in shallow well applications. They have been shown to be more economical than metal screens, resisting corrosion from the salts and gases commonly found in fresh or salt water.