0

-

An empty cart

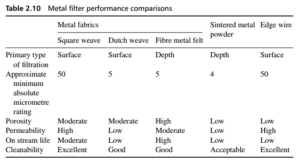

You have no item in your shopping cart

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121The crimping of the individual wires in a mesh goes a long way towards ensuring the stability of the mesh, and therefore the constancy of the apertures of the mesh, if the mesh is subject to movement or vibration in use. Where absolute stability is required, this can be achieved by sintering the mesh, so that the wires fuse together at their contact points.

Sintering is even more important in maintaining the stability of multi-layer meshes. Composite constructions of wire mesh, consisting of several layers of mesh sintered together, are aimed at producing a high strength porous sheet of greater

durability than single layer mesh. At the same time, the layer construction provides filtration in depth, with increased dirt-holding capacity.

As a general rule, different meshes are used for each layer, chosen and oriented to provide optimum strength with a minimum of masking of apertures in adjacent

layers. Final bonding is then achieved by sintering, resulting in a porous one-piece material that is dimensionally stable with minimum possibility of delamination. The lower layers are usually of coarse mesh to provide the strength; then there will

be one or two layers of fine mesh for the filtration, topped by a coarser back-up layer. Nominal ratings for such media can be as low as 5 um.

For further information, please click here.