0

-

An empty cart

You have no item in your shopping cart

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121Just as needlefelts took market shares from some woven fabrics as filter media, so now are the newer meltspun synthetics expanding quickly into most filtration applications. These are the class of media that start with a filament of molten thermopolymer being extruded from a fine nozzle. As it leaves the nozzle the filament is quenched rapidly in an air stream, and then laid down on a belt moving along below the extrusion nozzle.

If a row of nozzles, or spinarets, is mounted across the width of the collecting belt, and is caused to oscillate in the direction of the nozzle row, then the filaments fall onto the belt in a random fashion, to form a continuous strip of material. This is then pressed at a temperature sufficient to melt the collected filaments at their points of contact to form a strong coherent material, a process called spun bonding. If an air stream just below the exits from the spinarets is directed across the path of

the falling filament, it will break the filaments into relatively short pieces, and the resultant fibres can then be collected on a moving belt, and pressed and sintered,

and this process is called melt blowing. It is this integral production of filament or fibre followed immediately by its laying down as the medium that distinguishes the spun media from the felts – which are made, usually, from bundles of fibre bought

in from a separate supplier.

Since the late 1960s, these novel manufacturing processes have developed rapidly, to give the resulting materials a commanding position in the filter media business. The development has been so rapid that a standard set of terms has not yet

been agreed on an industry wide basis – some refer to all such materials as spunbonded, others differentiate between spunbonded and meltblown, while terms such as melt spun and flash spun are also used, while the latest very fine fibre materials are also called spun webs. The earliest such processes were those first called melt spinning, now generally known as spun bonding, and which remain important to the present day. They produce relatively coarse filaments, while the newer developments, such as melt blowing, have enabled the production of much finer fibres. Spunbonded media are the stronger, and are often found as a sandwich structure, with a layer of spunbond in each side of an inner layer of meltblown material.

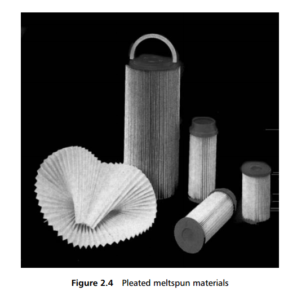

The meltspun materials are usually formed into thin sheets, like paper or cardboard, and are then widely used in pleated form, as cartridges, shown typically in Figure 2.4. These media are capable of exceedingly fine degrees of filtration, and a

great deal of microfiltration is now undertaken with them.

The differences between the two main classes of dry-laid spun material are significant in terms of filtration behaviour, but both are available with the same range of finishing processes as are used for woven and needlefelt materials: calendering,

singeing and coating. The lamination of different materials is also an important feature of dry-laid spun media.

The latest technique, of major interest because of its ability to produce very fine (nano) fibres, is electrospinning. This uses an electric field below the spinneret to draw out the filament before it is laid down as the finished material, with final filament or fibre diameters controlled by the electric field.

For further information, please click here.