0

-

An empty cart

You have no item in your shopping cart

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121Soybean is an important source of protein, and the process to recover the protein and fat requires the removal of undesirable compounds. Traditional removal methods include extraction, heat treatment and centrifugation to separate the protein and

fat from these compounds. Hollow fibre ultrafiltration modules are used to recover full fat soy protein concentrates and soy isolates.

Animal product processing utilizes ultrafiltration to remove biologically degradable matter from wastewaters to give a permeate suitable for discharge to a sewage system.

Fruit juice processing is a major use for membrane filters, particularly for clarification (using microfiltration or ultrafiltration), concentration (using reverse osmosis) and deacidification (using electrodialysis). The clarification of apple juice by ultrafiltration is now an important process, whether making clear juice or ‘ natural ’ (i.e. cloudy) ones.

Developments continue on citrus fruit processing. The membrane configurations most often used in juice clarification are tubular membranes or hollow fibre modules, as well as plate and frame systems using flat sheet membranes. The traditional

method of concentrating juices and purees has been evaporation, but nowadays reverse osmosis is proving successful. Reverse osmosis plant performance depends on juice viscosity, the osmotic pressure of the solution, and the constraints imposed by the need for a particular product quality.

Potential applications of membrane processes in cereal production are in the trea tment of stillage, in corn wet milling operations, evaporation of steep water, concentration of dilute sweet waters, and in polishing of reverse osmosis permeate and evaporator overheads. Corn proteins can be recovered from stillage solubles of dry milled fractions of corn, grits, flour, degerminated meal, etc. by reverse osmosis.

Ultrafiltration is also used to fractionate and concentrate proteins from potato processing wastewaters. Other protein wheys can be processed by reverse osmosis. Electrodialysis is used for a number of applications in the food and beverage industry, including deionization or deacidification of fruit juices, wines and, in the dairy industry, milk and whey. It often competes directly with ion exchange processes.

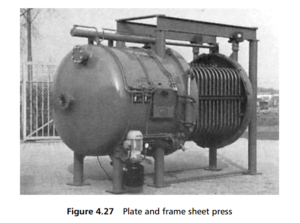

Whilst membrane filtration has made great progress in the food and beverage industries, the more traditional sheet filter still holds an important part of the business. Typical filter sheets used in beverage processes are designed to be of a standard

thickness, and to use only natural kieselguhr and perlites. Other sheets use natural kieselguhr as the filtration active ingredient combined with processed wood pulps as extenders. Pure cellulose sheets incorporating wet strength resins within the matrix of the sheet are used in plate and frame filter systems (Figure 4.27). Filter aids may be applied initially as a precoat layer and subsequently as an addition to the main feedstock. Other filter sheets include the addition of activated carbon.

In wine production, chemical and biological stability are vital. To achieve chemical stability, it is essential to eliminate from the wine excess amounts of heavy metals such as iron and copper, of tartrates and sometimes of albumens. For biological

stability, it is necessary to ensure the wine is free from yeast and bacteria. Filtration plays a major part in these separation processes. Sheet filters, consisting of a flush plate filter or a plate and frame filter press, are used as standard equipment in the wine industry. Standard sizes use 40X40 cm or 60X60 cm elements.

The metal surfaces of the filter plates and the expanded metal inserts and filter frames, in contact with the wine during processing, are preferably made from 316 stainless steel with smooth polished surfaces to prevent microbiological contamination. The first stage at which wine is filtered is likely to be at the time of first racking.

Generally, kieselguhr is used as the filter medium. For this purpose, the plate and frame filter is usually dressed with a high wet strength cellulose sheet suspended over, and supported by, the outlet collection plate. The precoat and filter beds are

deposited on the cellulose sheet and the bed is built up in the inlet frames or chambers on either side of the outlet plate. The filter is cleaned at the end of a cycle and sheets can generally be used again.

The quantitative performance of the filter is dependent on the hourly flow (which in turn is dependent on the filtering surface area) and on the total throughput per cycle (which is dependent on the available cake volume).

In the brewing industry, the filtration of fermented beer, following a period of cold storage, is still widely practised as a two-stage operation with final sheet filtration. The first removes visible turbid matter and uses kieselguhr as the filter medium in a filter press. For sheet filtration as a final stage, it is important to use stabilizing sheets to give the beer greater stability against chill and oxidation hazes by removing a proportion of anthocyanogens and to shorten the cold storage time.

The filtration of whiskies prior to bottling, of either blended or straight malt types, is essential to ensure shelf-life, stability and clarity. The process is by no means straight-forward, and it is of importance that the correct equipment and filtration media are utilized, and that the filtration is conducted under carefully controlled conditions. Filter presses are generally used to remove chemical and physical hazes, including ethereal oils. It is common practice for whiskies to be chilled prior to final filtration to assist the build-up of large globules of oils on the filter sheet surfaces. The presence of air in whisky must be excluded during filtration.

In the soft drinks factory, the main ingredients to be filtered are the sugar syrup and water for the bottling process. Filtration of sugar syrup is a batch process, in which measured quantities of sugar and water are mixed together, filtered under pump pressure and transferred to a vat. Filter presses are used extensively for sugar syrup filtration. Filtration rates for sugar syrup solution will vary according to viscosity, quality of sugar, etc. from as high as 950l/m2h to as low as 300l/m2h.

Outside the food and beverage industries, there are many other applications for sheet filtration. Some of the more important include antibiotics, medicinal syrups, toilet and cosmetic preparations, gelatine and vinegar.

Gelatine liquor usually involves a multi-stage filtration process. Primary filtration removes coarse particles of suspended matter, and secondary filtration further improves the clarity and imparts a brilliance to the liquor. Where the gelatine liquors are to be passed through ion exchange columns, coarse filtration takes place before the deionization stage. The primary operation is best accomplished with kieselguhr as the filter medium. Washable type support sheets are used. Secondary filtration should occur at a stage in the concentration process where the combination of throughput and viscosity is considered ideal for optimizing the filter specification.

Vinegar is normally filtered at the bottling stage. Sterilizing filter sheets are required for malt and wine vinegars.

Look for more information, please click here.