0

-

An empty cart

You have no item in your shopping cart

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121It was stated earlier that industrial filter applications can be divided broadly into two groups, those providing a service to a factory operation, the utility filters, and those acting as a main production unit, the process filters. It was further stated that

the utility filters were largely concerned with clarification of a fluid, and so with system protective and contamination preventive duties, and that this Handbook is primarily concerned with this type of filter, which, on the whole, is a small device.

Nevertheless, for the sake of completeness, if nothing else, some mention must be made of the range of process filters, as has been done in Section 3, to be supplemented here with notes on some process applications, largely for the cartridge and

membrane filters mainly associated with utility duties. Membrane processes are increasingly finding application in a wide range of processes, including:

● purification of water and feed materials

● purification of solvents

● elimination of solvent-using processes, thereby increasing intrinsic process safety, and aiding the drive towards environmentally friendly processes

● increasing product yields

● continuous removal of reaction products, to increase the rate of reaction (as in membrane reactors)

● recovery of catalysts

● purification and concentration of low molecular weight organics

● separation of reactor by-products as purified streams

● separation of liquids from reactions such as dehydrogenation, oxidation, esterification, etherification, and dehydration, and

● concentration of slurries and suspensions.

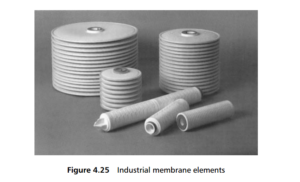

Some typical industrial membrane elements are illustrated in Figure 4.25, which shows pleated sheet membrane and lenticular elements.

Spirally wound membrane modules can generally meet most process application requirements. They are particularly suitable for sanitary applications in the pharmaceuticals, biotechnology, dairy, food and beverage industries. They are also

widely used in the industrial sector for environmental protection, metal coating, chemical and paint applications.

Hollow fibre membrane modules are more suited for applications that require high packing density and high purity. Typical areas of application include wine filtration, and pure water production for pharmaceuticals and electronics, as well as surface water treatment and use in a membrane bioreactor.

Multi-tubular membrane modules are best suited for feed streams with higher levels of suspended solid content, such as sludge concentration in wastewater treatment, degreasing plant bath life extension, oily wastewater treatment and paint recovery.

In the processing industry in general, a well-designed filtration system must remove the contaminants within specified limits, and must continue to maintain the quantity of filtered solution over the service life of the filter. A properly sized and

well thought out filtration system can save headaches as well as money. An oversized system wastes filter medium, especially if this needs changing frequently for other reasons, and involves investment in unnecessary hardware. An undersized system

does not perform as efficiently as expected and requires premature replacement of the filters. System sizing is best carried out by a trained applications specialist, who may use several methods to make a determination of the specific needs of the process that maximizes filter performance.