0

-

An empty cart

You have no item in your shopping cart

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121Magnetic separators, so called in the industry, are confusingly exactly the same in principle as a magnetic filter or a magnetic clarifier: attracting and retaining ferro-magnetic solids contained in a product being treated. Particular spheres of application are for the removal of harmful metallic particles and sludges from coolants in re-moulding and machine tool systems, and for mineral processing. A magnetic separator is an ideal choice of clarifying system where the use of coolant lubricants depends on clean fluids such as emulsions, aqueous solutions and cutting or grinding oil.

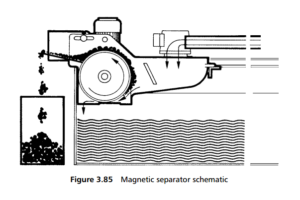

In operation, contaminated working fluid flows through a channel into an inlet box and then into a separating zone, shown diagrammatically in Figure 3.85. A magnetic rotor turns slowly against the direction of the flow. The magnetic field acts on the ferritic contamination along the entire width of the rotor. Ring magnets attract the magnetic particles along with adherent non-magnetic dirt particles, and convey them to a scraper plate mounted at an angle to the magnetic rotor, allowing any residual fluid to flow back into the container. The sludge taken from the rotor builds up on the scraper plate,

dries and is conveyed to the dirt tank by the following grinding sludge. Flow rates for this type of magnetic separator depend on the type of inlet and its arrangement.