0

-

An empty cart

You have no item in your shopping cart

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121A small but important group of what are, in effect, single cartridge filters are operated in such a way that they can be continuously cleaned by an automatically functioning mechanism. These are called self-cleaning filters (and in some industries, automatic filters – although a wide range of filter types can be arranged to operate automatically).

Basically, the self-cleaning filter is a cartridge element mounted vertically in a housing that contains the cleaning mechanism. This mechanism moves across the outer (upstream) face of the element, cleaning a small area as it moves, and its movement is such as to cover the whole of the filtration area of the element in one cycle, before it returns to its starting position. It may then repeat the cleaning process immediately, or pause for a while before doing so.

The cleaning mechanisms used for this purpose consist of a reverse jet of filtrate coming from inside the element, or a jet or spray playing on the filtration surface, or, most commonly, a brush or scraper moving over the outside of the element (where the solids are collected) to brush or scrape the solids away from the filter surface, to fall into the base of the housing, from which they are periodically removed. (Less often, the cleaning device is kept stationary and the cartridge element is rotated against the brushes or scrapers to remove the collected dirt.) The brushes or scrapers may move around the cartridge, or up and down parallel to the axis of the element.

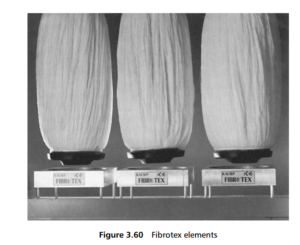

A very different type of self-cleaning filter is the Fibrotex element, developed by Kalsep, illustrated in Figure 3.60. The element is a bunch of fibres, which acts as a

depth filter when the bunch is twisted together. When full, the bunch is untwisted, loosening the spaces among the fibres, and allowing collected contaminants to be blown free and discharged.