0

-

An empty cart

You have no item in your shopping cart

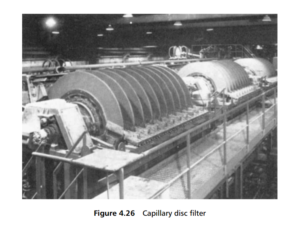

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121An interesting extension of the range of vacuum filters is the capillary disc filter ( Figure 4.26 ). This is a continuously operating, capillary action, ceramic dewatering filter, which eliminates the need for separate filter cloths. The filter medium is a disc, formed from two circles of sintered alumina, joined at their circumferences. The filter has several such discs mounted on a central horizontal shaft. The medium is practically inert in most solutions, and may be used in a broad range of water-based and solvent-based slurries. In operation, as the microporous ceramic discs rotate through

the feed slurry, capillary action and an almost complete internal vacuum draw liquid through the medium to the inside of each disc.

Some liquid is retained in the micropores as a result of surface and interfacial tension effects, preventing either air or solids from passing through the medium, and resulting in the solids building up as cake on the outside of the discs. The filter cake

has an extremely low moisture content. Scrapers remove the cake leaving a thin coating on the disc surface, which acts as protection against mechanical abrasion. Filtrate is then used to flush the plates removing the residual heel in a backflow washing process. Typical filtration area for the capillary disc filters ranges from 5 to 45m2, and the number of discs can be from 6 to 20 or more.