0

-

An empty cart

You have no item in your shopping cart

The vibratory filter is a high intensity magnetic filter, specifically used for removing fine iron bearing contaminants from mineral slurries and other fluid media, as well as from free-flowing streams of solid particles. Typical fluid applications include

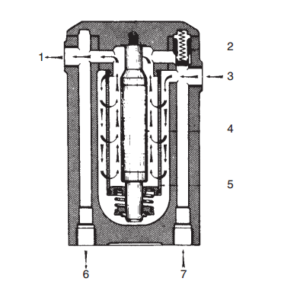

Figure 3.84 High pressure microfilter with magnetic and mechanical elements. 1, Side outlet; 2, relief-valve; 3, side inlet; 4, magnetic filter; 5, replaceable microfilter element; 6, alternative bottom outlet; 7, alternative bottom inlet.

the processing of ceramic slips and glazes, clays, inks and toners, while powders treated include fine sands, glass powders, talc, and silica and zircon flours.

In operation, a solenoid electromagnet generates a magnetic field into the bore of the coil. A filter element of expanded metal placed in the coil concentrates the flux of the magnetic field. This produces a myriad high gradient collection zones that capture magnetic contaminants as the feed material filters through the element. To enhance the fluidity of the very fine powder as it passes through the matrix, the canister is attached to two high-frequency, low-amplitude vibratory drives. When feed materials flow through the magnetized matrix, the iron bearing contaminants are captured and held.