0

-

An empty cart

You have no item in your shopping cart

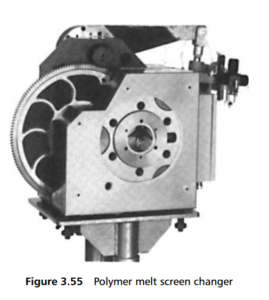

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121Somewhat akin to the capsule filter in operating principle, although very different in construction and operating conditions, are many of the filters used to remove contaminants from the flow of molten polymer on its way to an extrusion nozzle.

The filtration of plastic melts presents a considerable challenge, and sets of standards have had to be introduced to meet the demands set by customers in the plastics processing industry. In particular, for a long time filtration over large surface areas could only be carried out using cartridge filters or filter screen packs with inherently unsatisfactory conditions in the melt channel.

As demands have grown for finer degrees of filtration in available filter media, the extruded fibres used in these media must also be made to a smaller and smaller diameter. This means that the extrusion process must produce smaller diameter material, and so the nozzles must be finer, which makes them more easily blocked by contaminant particles – unless these, in turn, are filtered from the melt. The filter media used for this task of polymer melt filtration have been discs of sintered powder, fibre or mesh.

Changing the medium employed in polymer melt filters required lengthy production interruptions, increasing material costs and lengthening the cleaning process. To overcome these and other manufacturing difficulties, continuous screen-changer

disc filters have been developed where the filter disc rotates between two plates ( Figure 3.55 ).

At present, rotary disc technology is the optimum solution for the filtration of high or low viscosity plastic melts. Constant production is a top priority for efficient manufacture of high quality plastics and rubber products, but efficiency of use and return on investment should also be primary considerations. The continuous screen-changer for constant melt filtration under control constant pressure has proved successful for filtering most extrudable thermoplastics, including polycarbonates, PPS, PEK and PVC. Melt pressures of up to 700 bar and temperatures up to 450°C can be dealt with, and screen surface areas range from 8–500cm2.

Ask for more information, please click here.