0

-

An empty cart

You have no item in your shopping cart

One of the most common sights in a power station or processing plant is the large chamber filled with an array of filter bags, known in some industries as a baghouse, and in others as a fabric filter. These are used on large exhaust gas streams, mainly

to prevent pollution from dust residues, but quite often for the recovery of valuable solids from the exhaust.

Although perfectly usable on the scale, and in the sizes of, liquid bag filters, the corresponding units for gas filtration are usually much larger, and are used in the multiple element installations, because they usually have to deal with very high

flow rates. For the small-scale treatment of gas streams, the pad and panel filters of Section 3J are most commonly employed.

The most common form for a gas filtering filter bag is a long, cylindrical sleeve or bag, mounted on a cylindrical cage made from metal rods, with support rings at regular intervals along its length. The bag is positioned vertically, usually with

its closed end at the bottom, hanging from a support plate with its open end fastened to a corresponding hole in this plate. Access above the support plate, and the method of fastening to it, allows individual bags to be withdrawn for replacement if

damaged or too clogged to be effective.

Dust capture can be effected on the inside of the bag (gas flow from inside out) or its outside (gas flowing from the outside), with the latter by far the most common, especially with the more automated baghouses. Dust cakes on the outside of the bag are more easily removed, either by shaking the bag assembly, or by a reverse flow of compressed air. Internally accumulated dust can be shaken into the bottom of the bag, but eventually the baghouse must be shut down and the bags removed for emptying.

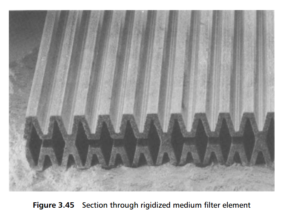

Dust accumulated on the outside of the bags, when blown off the bag surface, falls into the hopper at the base of the baghouse. A large proportion of baghouse systems use a pulse jet blow-back (Figure 3.44), in which each bag has a separate

valve from a compressed air supply above it, so that any bag can be blown free of

accumulated dust cake, either a bag at a time in turn, or in small groups. In this way, the bags can be kept free of collected dust without the need to shut the whole baghouse down for the purpose. There is sufficient elasticity in the bag material so

that the pulsed jet causes a slight expansion in the bag, which cracks the cake, making its release much easier.

The material of the bag, and the baghouse construction, can be selected to suit the nature and characteristics of the dusts to be handled. The main system parameters of concern are particle size and density, their abrasive nature and hygroscopicity, and their tendency to form aggregates. Also to be taken into account are the electrical properties of the particles, particularly if the dust suspension is potentially explosive. In this latter case, the chance of auto-ignition or explosion, triggered by a spark from electrostatic charges, can be eliminated by the use of anti-static media, such as synthetic fibres interwoven with metallic or carbon fibres, and with an earthed connection. Bag fabrics can also be treated for water repellence, to give fire resistance, and with special surface coatings either to improve filtration performance or give easier cake release.

For a considerable part of the history of the baghouse, the main material of the bags was a woven fabric, using natural fibres. Once felts became available with sufficient strength, at first plain felts laid on a strong scrim, and then needled, these

rapidly took a share of the baghouse market, mainly on economic grounds. Felts had a more homogeneous construction, enabling a greater dust retention capacity, usually at lower pressure drops, but their greater depth filtration action required a more rigorous cleaning action.

Synthetic nonwovens, such as spunbonds and SMS sandwich media, are now an important component of the baghouse filter media, often pleated to accommodate more filtration area in a given housing (with a protective layer of very coarse mesh

outside the pleats to retain them in position when the bag is backflushed).

The often hot nature of exhaust gases leads to the frequent use of PTFE/Teflon as the material for bag media, as well as the newer Tefaire (a needlefelted blend of 25% glass and 75% Teflon fibres). Other temperature resistant materials include a

range of polyimide fibres, especially for minerals processing and cement production exhausts.

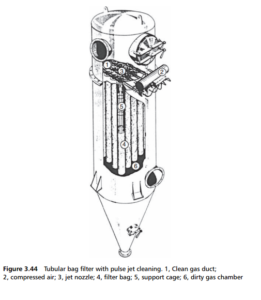

A very different type of element, although employed in the same type of structure and layout as the baghouse using bag filters, is the rigidized media element, developed in Germany by Herding. In place of the flexible fabric-style medium, the

element is flat, with two long sheets of rigid porous plastic joined around the edge, and with each sheet deeply corrugated parallel to their long side, to increase the filtration area, as shown in Figure 3.45.