0

-

An empty cart

You have no item in your shopping cart

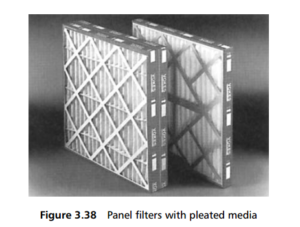

The flat elements employing a thick filter medium and working by depth filtration, are distinguished here, as filter pads, from those using thin sheet media and working by surface filtration, which are called filter panels. The basic need of all kinds of filter is to maximize the available filtration area, and a single thin sheet would not present sufficient area to make it an economic concern. The solution is to corrugate the sheet by pleating it with concertina-like folds parallel to one long side of the panel, and with each fold as deep as the depth of the containing frame (as shown in Figure 3.38 ).

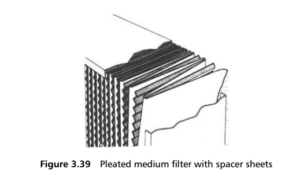

The pleats can be formed at any spacing, to give the filtration area required. This can result in pleats that form a wide V-shape or a narrow U-shape. It is necessary to ensure that, whatever the pleat shape, the full area of the medium is available

for filtration. The narrower pleats are at risk of pinching together, and thus losing effective area, so these will often be found with spacer sheets incorporated between the folds of the filter medium (as shown in Figure 3.39), where the spacer sheets

are corrugated in a direction perpendicular to that of the filter medium.

Panel filters can be made from any material that can be pleated, without cracking along the fold: cellulose or glass paper, fine wire cloth, woven fabrics, nonwoven fabrics of all kinds (felts, spunbonds, meltblown) and membranes. Charcoal cloth

can also be used, provided that it is pleated before charring. Synthetic fibre media are most common, having shown themselves well suited to the ventilation of a wide variety of buildings: domestic, commercial, institutional and industrial.

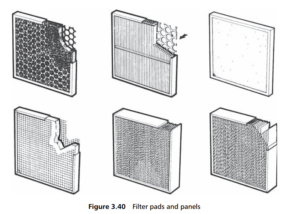

Figure 3.40 shows a variety of filter pads and panels with their methods of construction.

The applications and efficiencies of dust collecting filters are given in more detail in Section 6, where it will be seen that filter panels can achieve very high filtration efficiencies. Such high efficiency filters are normally installed in series with a prefilter, using coarser filter medium, to remove larger particles from the inlet air, which would block the fine filter too quickly.

The panel filter, because it works basically by surface filtration (or by creating a thin cake on its upstream surface), should be cleanable mechanically (by a sharp rapping over a dust collection hopper) or by back washing with water or a suitable

cleaning liquid (followed, of course, by careful drying). Some panel filters are quite expensive, so the ability to clean them and return them to functional use can be an important feature in their selection.