0

-

An empty cart

You have no item in your shopping cart

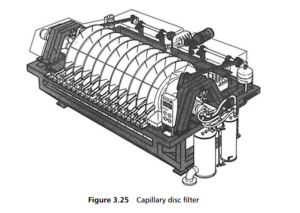

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121The capillary disc filter looks like any other standard rotary vacuum disc filter, as can be seen in Figure 3.25 , but the filter medium is a finely porous ceramic disc, which draws filtrate through the disc material by capillary action, under the applied

vacuum. The filter discs are made of sintered alumina with uniform micropores less than 1um in size, which allows only liquid to flow through it. Despite an almost absolute vacuum, no air penetrates the filter material. The disc material is inert,

resistant to almost all chemicals and slurry temperatures, making the system very versatile for the chemical, mineral, metallurgical and waste processing industries.

Cake formation takes place on the discs as they rotate through the slurry. A vacuum pump creates a very high vacuum level, which draws liquid through the discs into the filtrate lines. Solids built up rapidly on the external surfaces of the disc and

the microporous structure prevents any solids from penetrating the disc surface. As the discs rotate, capillary action continues uninterrupted across the disc surface until all free liquid is removed from the solids. The accumulated cake is exceptionally dry, and is removed from the disc surface by a set of scrapers, leaving a thin heel on the surface to protect the disc from mechanical abrasion.

Some filtrate is used to back-flush the discs. This removes residual cake and cleans the microporous structure of the discs. The discs will eventually become clogged, and the ceramic plates can be regenerated, and full permeability restored, by ultrasonic cleaning on a regular or periodic basis, alone or in combination with chemical cleaning.

Although disc-type vacuum filters are not normally well suited for cake washing (because the wash water runs too quickly off the surface of the cake), the capillary action filter has proved the exception. Wash liquid is sprayed on the cake solids, to

remove additional filtrate or impurities. This displacement washing is not susceptible to the difficulties of conventional filtration systems, where cake cracking, channelling or uneven distribution occurs.

Capillary filtration can provide for a high product output capacity with the produced filter cake having a very low water content. Disc filters of this type are considered to be energy efficient, using up to 90% less energy than other vacuum

filters, because no air passes through the plates.