0

-

An empty cart

You have no item in your shopping cart

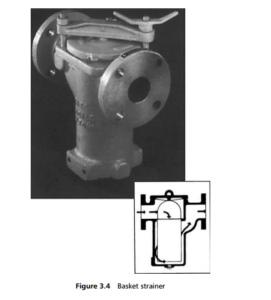

Permanent strainers are conventionally complete fittings, most commonly with a housing of Y-configuration, with a cylindrical strainer element (as in Figure 3.2 ). They can be used in both the horizontal and vertical planes, and are intended for applications where only a low concentration of contaminants is expected. The element is retained in its housing by a plug end, which may be plain or fitted with a valve that can be opened for blow-through cleaning. In either case, the element

itself is removable and so this type can also be used as a temporary strainer. Typical data for the cut-points of wire mesh Y-type strainers are given in Table 3.2 , while pressure loss data are included in Figure 3.3 .

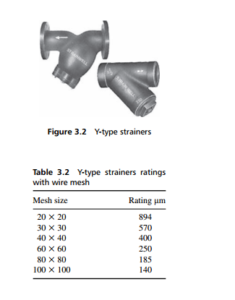

Single basket-type strainers, such as that shown in Figure 3.4 , with large filtration areas, are used for high flow debris collection in pipelines, and on the suction and discharge sides of pumps. They may be used in-line or off-line, and can be made of cast iron, cast steel, stainless steel or bronze, depending on the application required. Applications can include wastewater systems, boiler feed pumps, lubricating and fuel oils, refining of crude oil, fire protection duties, various marine

applications, and in the process industry for the protection of flow meters, heat exchangers and pumps.

The principle advantages of basket strainers is that they can provide a greater dirtholding capacity and can have easier access for removing the strainer for cleaning. They normally have a higher pressure drop than simpler Y-type strainers, as can be seen from Figure 3.5 .