0

-

An empty cart

You have no item in your shopping cart

envato-wordpress-toolkit domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121g5plus-darna domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /var/www/wp-includes/functions.php on line 6121The industrial context within which filter media are made and supplied to their endusers is of more than passing interest. The great variety in which media are made leads to a corresponding variety in the types of company involved with the supply

of media. Some are devoted to its manufacture, while for others it may be only a small part of the total company activity.

Five main stages can be seen in the industry. These are the:

1. maker of the basic material from which the medium is to be made: a metal wire, a natural or synthetic fibre, a ceramic powder, an extruded plastic filament, and so on

2. conversion of some of these basic materials into a form in which they can be used to make filter media: the spinning of fibres or the twisting of filaments into a yarn, the crimping of a wire, etc.

3. formation of the bulk medium: the weaving of a cloth or monofilament mesh, the moulding and sintering of a mass of plastic or metal fibre or powder, the production of paper, the preparation and processing of a sheet of membrane (all together with any necessary finishing processes)

4. conversion of the bulk medium material into pieces of the particular size and shape required for the medium to fit the filter (especially for makers of replacement media for existing filter units), which may include, for example, the pleating of flat material

5. making of the filter itself, including the fitting or adapting of the medium to its position in the filter.

A sixth stage – the distributor or wholesaler – frequently stands at the end of this process, serving the end-user, and may exist at several inter-stage points in this series. The creation of a stand-alone filter element, such as a cartridge, might be considered as part of stage iv, or as a further stage between stages iv and v – and then bypassing stage v, by direct sale to the end-user.

Many companies in the industry exhibit combinations of two or more of these manufacturing stages (vertical integration), but this may result in limitation of the markets for the products of the earlier stage.

Some media, of course, do not exhibit all these stages: sand filters go from the supplier of the graded sand straight to the deep bed filter maker. Most, however, show several, with some of the most common (woven fabrics, needle felts) exhibiting all of them. This complicated market structure obviously has its impact on a review of this nature – which basically looks only at the products of stages iii and iv.

The filter media business is a large one. It is estimated that the global market for media of all kinds will be about $21 billions in 2007, and is growing at about 5.5% per year. This market value is counted after stage iv in the above manufacturing

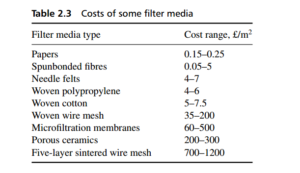

chain, i.e. at the point where the finished filter medium is about to be inserted into a filter. The costs of filter media vary extremely widely even within one type, let alone among the different types, as is shown in Table 2.3 .

For Further information, please click here.