0

-

An empty cart

You have no item in your shopping cart

Filter paper is a semi-permeable paper barrier placed perpendicular to a liquid or air flow. It is used to separate fine substances from liquids or air.

Filter paper comes in various porosities and grades depending on the applications it is meant for. The important parameters are wet strength, porosity, particle retention, flow rate, compatibility, efficiency and capacity.

There are two mechanisms of filtration with paper; volume and surface. By volume filtration the particles are caught in the bulk of the filter paper. By surface filtration the particles are caught on the paper surface. Filter paper is mostly used because even a small piece of filter paper will absorb a significant volume of liquid.

The raw materials are different paper pulps. The pulp may be from softwood, hardwood, fiber crops, mineral fibers. For high quality filters, dissolving pulp and mercerized pulp are used. Most filter papers are made on small paper machines. For laboratory filters the machines may be as small as 50 cm width. The paper is often created to improve porosity. The filter papers may also be treated with reagents or impregnation to get the right properties.

Filter papers are widely used in laboratory experiments across many different fields, from biology to chemistry. The type of filter used will differ according to the purpose of the procedure and the chemicals involved. Generally, filter papers are used with laboratory techniques such as gravity or vacuum filtration.

Quantitative filter paper, also called ash-free filter paper, is used for quantitative and gravimetric analysis. During the manufacturing, producer use acid to make the paper ash-less and achieve high purity.

Chromatography is a method chemists use to separate compounds. This type of filter paper has specific water flow rate and absorption speed to maximize the result of paper chromatography. The absorption speed of this type of filter paper is from 6 cm to 18 cm and the thickness is from 0.17 mm from 0.93 mm.

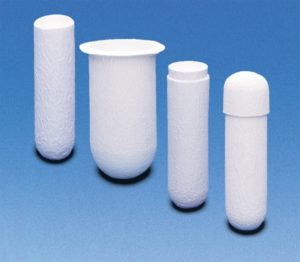

Extraction thimbles are rod-shape filter paper often used in Soxhlet extractors or atomized extractors. It is ideal for very sensitive detection, the performance it depends on the thickness of inner diameter. Also, it is usually used in areas of food control and environmental monitoring.

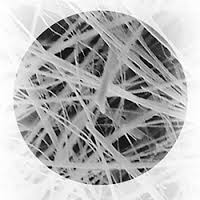

Glass fiber filter has the pore size of 1 µm, it is useful for filtering highly contaminated solutions or difficult-to-filter solution. Also, glass fiber filter has extends filter life, wide range of particulate loads and can prevent sample contamination. In addition, different types of glass fiber filter are suitable for different filtration situation. There are 7 different types of glass fiber filters and the major difference is thickness.

Quartz fiber filter paper is high resistance chemical, does not absorb NOx and SOx dioxides, unaffected by humidity and easily sterilized. Thus, it is mostly use for air pollution analysis.

PTFE filter has wide operating temperature (-120 °C~260 °C) with high air permeability. The resistance of high temperature makes PTFE filter paper autoclavable. It is often use for filter hot oils, strong solvents and collecting airborne particulates.

Engine oil is filtered to remove impurities. Filtration of oil is normally done with volume filtration. Filter papers for lubrication oils are impregnated to resist high temperatures.

Tea bags are made from abacá fibers, a very thin and long fiber manilla hemp. Often the paper is augmented with a minor portion of synthetic fibers. The bag paper is very porous and thin and has high wet strength.

For further information, please check here.